ETH Zurich develops smart textiles: motion detection via sound waves

Using specifically woven-in glass fibres and piezoelectric transducers, a fabric is created that can detect even the smallest deformations. In future, it could be used in sportswear, medical monitoring or interactive VR equipment.

The ETH Zurich has developed a new type of textile that recognises movement not with cameras or chips, but with sound waves. It uses finely woven glass fibres that register even the smallest changes in the fabric. Under the name Sono Textiles, the technology promises precise measurement values and a high level of suitability for everyday use.

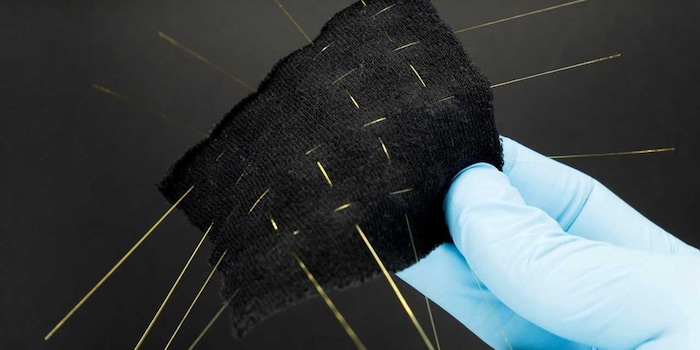

High-tech in fabric: glass fibre instead of chip

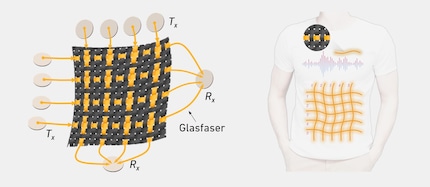

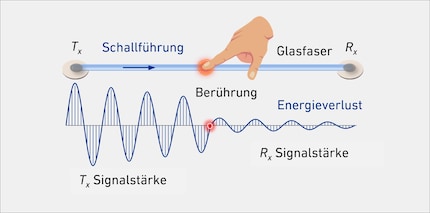

The principle is as simple as it is ingenious: Several glass fibres are woven into a textile at regular intervals. At one end of each fibre is a transmitter that emits ultrasonic waves. The acoustic signals are channelled through the fabric and a central receiver measures how much they change as they pass through: for example, when the material is stretched, pressed or moved. This creates an acoustic pattern that changes with every form of movement.

Source: Yingqiang Wang / ETH Zürich

A MISO system (Multiple Input, Single Output) is used accordingly. Several transmitters (Tx in the illustration above) transmit at different frequencies, the signals reach a single receiver (Rx), which reduces the number of components. This also allows individual touch or movement points to be clearly assigned, the researchers explain in the study «A smart acoustic textile for health monitoring», which was published in Nature Electronics. This should ensure efficient and detailed data processing.

In contrast to classic wearables, the system does not require any electronics on the skin. No batteries, no cables, no rigid modules. Just fabric with built-in intelligence.

For sport, gaming and smart clothing

This is particularly exciting for sports enthusiasts: according to the researchers, the Sono Textiles can precisely record movement sequences, for example during running, yoga or strength training. This opens up new possibilities for digital training analyses without having to wear gadgets. The textiles should also continue to be breathable.

Source: Yingqiang Wang / ETH Zürich

The fabrics could also be used in gaming or in the VR world, for example in gloves or suits that transmit gestures and movements directly into the game. The technology is so light and flexible that it can be easily integrated into everyday clothing.

Washable, robust, suitable for the masses

The Sono Textiles are also designed to be washable and robust. Because they do not require sensitive electronics, they can withstand more than many current smartwear products. And they hardly need any energy.

The ETH researchers say they are focussing on cost-effective materials and scalable production. This also makes the technology interesting for the mass market. For example, for sports brands that want to make smart clothing ready for series production.

Still in development but with a clear goal

The whole thing is not yet ready for the market. The first prototypes are working reliably in the laboratory, for example for breath monitoring or gesture recognition. However, the integration of all components, from the power supply to data acquisition and wireless transmission, is still a work in progress. Long-term stability with frequent washing or heavy use also needs to be tested further.

The glass fibres are still incorporated into the textiles manually. Automated production would be necessary for industrial use. This would be conceivable using digitally controlled weaving machines, for example. The researchers are working on implementing this step as cost-effectively as possible.

My interests are varied, I just like to enjoy life. Always on the lookout for news about darts, gaming, films and series.