Too Many Lathes? How to Choose the Right One

Here are five key factors to consider when selecting the perfect lathe for your needs.

Last updated 4 days ago. Automatically generated content.

Select options and limit the number of products

Max. Speed refers to the highest rotational speed a lathe can achieve, impacting the efficiency and precision of machining operations. Selecting the appropriate speed is crucial for optimizing performance, ensuring quality results, and accommodating the specific material and tooling requirements.

Popular options

3001 - 5000 rpm

Typical price

420,– to 710,–Offers enhanced speed for more complex tasks and harder materials.

Recommended for professional settings where precision and efficiency are prioritized.

Bestseller

5001 - 7000 rpm

Typical price

270,– to 490,–Allows for high-speed operations, beneficial for intricate and demanding machining.

Perfect for advanced users seeking superior performance in specialized applications.

Bestseller

Max. turning diameter refers to the largest diameter of a workpiece that a lathe can effectively handle and shape. Choosing the right turning diameter is crucial as it directly impacts the size of the projects you can undertake and the versatility of the lathe.

Popular options

Up to 100 mm

Typical price

340,– to 750,–Designed for small-scale projects, such as intricate parts and detailed components.

Ideal for hobbyists and small workshops, offering precision and efficiency in limited spaces.

Bestseller

101 - 200 mm

Typical price

180,– to 460,–Suitable for medium-sized projects, balancing between small and large-scale work.

Perfect for general-purpose use in professional settings, providing versatility across various tasks.

Bestseller

201 - 300 mm

Typical price

160,– to 680,–Capable of handling large workpieces, suitable for industrial applications.

Recommended for heavy-duty projects, offering robustness and adaptability in demanding environments.

Bestseller

The diameter capacity of a lathe determines the maximum size of workpiece it can handle, impacting the versatility and application range of the machine. Choosing the right size is crucial for efficiently performing tasks and ensuring the lathe meets your specific needs, whether for small projects or larger industrial applications.

Popular options

Up to 200 mm

Typical price

51,– to 260,–Ideal for small-scale projects and detailed work, accommodating smaller workpieces.

Best suited for hobbyists or workshops with limited space, offering precision and cost-effectiveness.

Bestseller

201 - 350 mm

Typical price

140,– to 320,–Offers a medium capacity for versatile applications, handling moderate-sized workpieces.

Suitable for professional workshops or users needing flexibility in project size, balancing capability and space requirements.

Bestseller

351 - 500 mm

Typical price

160,– to 2700,–Designed for larger projects, capable of managing substantial workpieces.

Recommended for industrial settings or users with frequent large-scale tasks, providing robust performance and efficiency.

Bestseller

The material of a lathe determines its durability and suitability for specific tasks, influencing precision and longevity during operation. Choosing the right material ensures optimal performance and efficiency, whether working with metals or woods.

Popular options (you can select more than one)

Metal

Typical price

150,– to 440,–Designed for precision machining of hard materials like steel and aluminum.

Ideal for industrial applications requiring high strength and durability, providing stable and accurate cuts.

Bestseller

Wood

Typical price

72,– to 260,–Crafted for shaping and cutting softer materials like timber and plywood.

Suitable for woodworking projects, offering smooth finishes and ease of use for intricate designs.

Bestseller

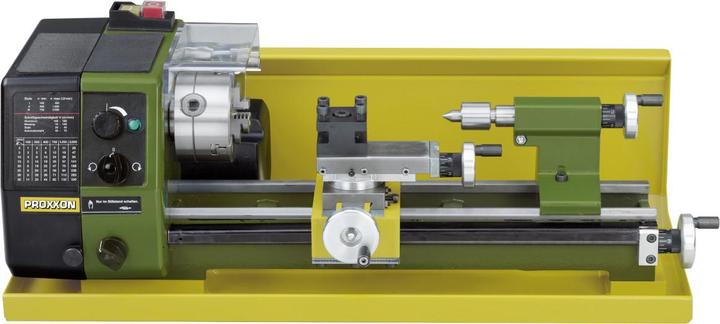

Choosing the right lathe brand can significantly impact the machine's reliability, precision, and longevity. Brands like Proxxon offer high-precision tools, while Holzmann provides robust models for heavy-duty tasks.

Popular brands (you can select more than one)

Proxxon

Specializes in high-precision, miniature lathes ideal for intricate work.

Favored by hobbyists and professionals for its accuracy and durability in detailed projects.

Bestseller

Holzmann

Known for robust, heavy-duty lathes suited for demanding industrial applications.

Offers reliable performance for users needing power and stability in their work.

Bestseller

Loc-Line

Renowned for innovative modular hose systems used in lathe coolant applications.

Enhances machine efficiency by optimizing cooling and lubrication during operations.

Bestseller