Background information

The solar racing car drives - but still without solar power

by Martin Jungfer

Long gone are the times when drivers of electric cars belonged to the automotive avant-garde. True pioneers are people like the students at ETH Zurich who are building a solar car from scratch. In October, the vehicle should be set to embark on an incredible journey.

In a few months’ time, the vehicle, which is entirely powered by solar energy, will be driving 3,000 kilometres across Australia. The Bridgestone World Solar Challenge spans a route from Darwin in the north of the continent all the way south to Adelaide. Teams from all over the world are currently working on vehicles for the race. Many of them are being built at universities, often with the help of corporations. This is also the case for the Swiss team at ETH, which is registered for the 2023 race in the Challenger Class. While only one person is permitted in the vehicle in this class, the Cruiser Class allows for a passenger. Almost 30 young men and women are involved in this project. The engineering students are part of a focus project that’s taking place over two semesters.

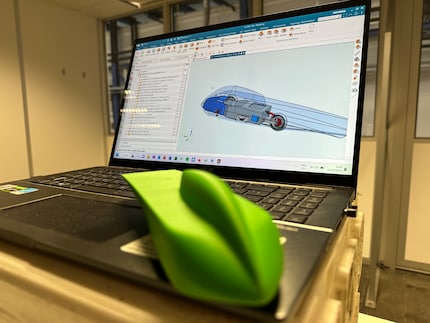

Throughout the project, you're more likely to find the students tinkering away at the workshop in Technopark, Zurich West, than in the lecture hall or library. However, for the time being, i.e. in early February, the race car only exists as a 3D CAD model on a computer. Lukas Hauser, Operational Lead of the team, shows me the current status of the project on the screen of a laptop. The computer sits in the middle of a barren room in Technopark. There are a few beverages in one corner, and some material in the other. The team members have made a model of the race car with the help of a 3D printer. They wanted to present me with something more tangible when I visited them. In this early stage, the car looks like a smiling dolphin.

Aerodynamics is an important ace to have up your sleeve at the race in October, Lukas explains. The team used computer simulations to calculate that the car will hit top speeds of over 100 km/h. On average, it will be driving at 80 km/h. And that’s through the power of the sun alone. No stops at a charging station will be permitted. The rules of the World Solar Challenge are strict. All teams from 24 countries must build their vehicle according to precise specifications:

The team has already determined one of the drivers. Jonas Rudin, the man in the wooden box in the header image, will be steering the solar car for a large part of the route. He’s already completed his studies and is currently working as a portfolio manager at Digitec Galaxus, taking care of the shop’s product range. The hundreds of thousands of kilometres of driving he’s accumulated during many a road trip have qualified him for the job. He’s probably relieved to hear that the people in charge of the design of the car plan on including a suspension. «That’s definitely needed, as there are many cattle grids on the roads in Australia,» he explains.

Nevertheless, it’s unlikely that the 3,000 kilometres, during which he’ll be taking turns with other drivers, will be a comfy ride. At least that’s what the mock-up of the future race car suggests. It’s on display in the adjacent room at Technopark and made up of OSBs that have been screwed together. No sign of high-tech here. There’s more of a soap box vibe. The mock-up’s used to see if the driver fits into the chassis. When he tested the seat, Jonas was given a cardboard «steering wheel» There’s not much wiggle room, that’s for sure. And the real version won’t be much different. But all that counts is that he can get out of the car in the prescribed time of 15 seconds max. It’s a necessary safety measure. After all, about half of the teams won’t make it to the finishing line. «In the past, there have been cases where the car was flipped over by a gust of wind,» says Jonas. Batteries can catch fire, tyres can lose air, electronics can fail.

These kinds of questions are keeping the team busy. The aim is to build an efficient, lightweight and therefore fast car – and a safe one at that. The team’s currently split up into small groups that are working on the final design and material for the streamlined shell. They’re also focussing on how to keep the driver’s cabin reasonably cool under Australia’s red-hot sun. Not to mention working on the solar cells that will deliver the power to the car’s electric motor. The students are also this close to finalising a sponsorship deal with a supplier. If all goes well, the supplier will build customised solar cells for the race car. These would have a significantly higher efficiency than that of a solar system on the roof of a house, for example. Of course, the students also want to max out the permitted area of four square metres to generate as much energy as possible – energy that goes straight to the drive when the car’s in motion. Or to the battery, so the car can get straight back on track in the morning, after the prescribed rest periods during the night.

The concept of a self-powered vehicle is put into action every other year since 1987 at the World Solar Challenge. And it might soon even find its way into commercial car manufacturing. Sono Motors is a Bavarian company whose Sion model is said to have a range of up to 305 kilometres simply by being parked in the sun. The Netherlands are also working on a similar project involving a car with a design that’s a tad sportier.

We’ll be publishing further reports on the ETH team’s progress in creating the race car in our magazine. Hopefully, right up to the grand finale when they cross the finishing line in Adelaide on 27 October. Do you have any questions about the project? Is there an aspect you’re particularly interested in? Let me know in the comments, and I’ll try to explain or elaborate on your queries.

Header image: Martin Jungfer

Journalist since 1997. Stopovers in Franconia (or the Franken region), Lake Constance, Obwalden, Nidwalden and Zurich. Father since 2014. Expert in editorial organisation and motivation. Focus on sustainability, home office tools, beautiful things for the home, creative toys and sports equipment.

Interesting facts about products, behind-the-scenes looks at manufacturers and deep-dives on interesting people.

Show all

Background information

by Martin Jungfer

Background information

by Martin Jungfer

Background information

by Martin Jungfer